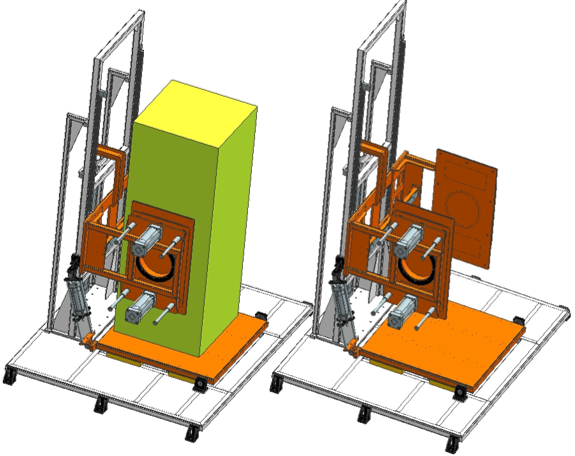

The Refrigerator Door Reliability Testing SPM is a fully automated testing system designed to evaluate the endurance and performance of refrigerator doors under repetitive operating conditions. This machine replicates real-life door usage cycles to ensure product durability, hinge performance, and latch integrity.

Equipped with a pneumatic actuation system, the SPM performs precise door open and close operations with adjustable force and angle, simulating long-term usage patterns. The system offers variable cycle time settings, allowing users to customize test parameters as per different product models or testing standards.

All operational parameters, including cycle count, speed, and test duration, are continuously monitored and recorded. The system provides real-time data visualization on an HMI interface and allows easy data export in Excel format for analysis and reporting.

Technical Highlights:

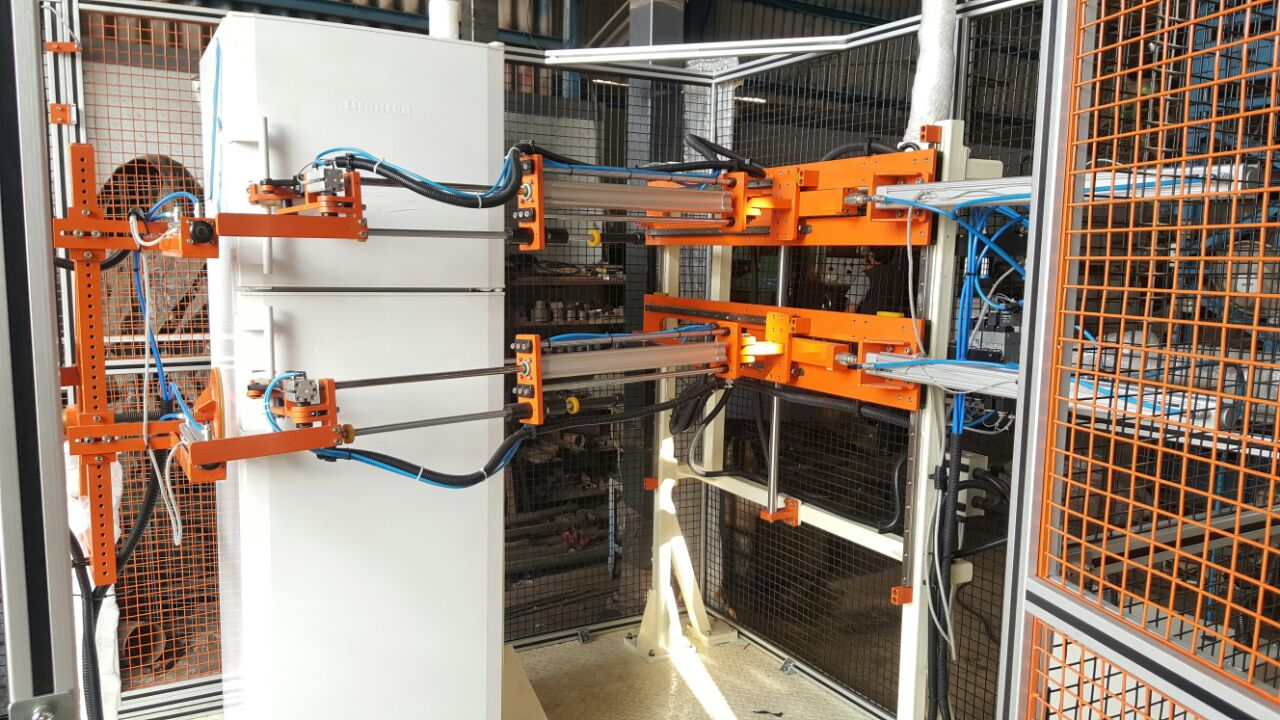

The Refrigerator Drop Testing SPM is a specialized automated system designed to evaluate the structural strength, rigidity, and durability of refrigerator assemblies during simulated handling and transportation conditions. This machine ensures that the product can withstand real-world impact forces without deformation or damage.

The SPM operates through a pneumatic lifting and dropping mechanism that allows precise control over drop height, frequency, and impact force. It enables users to conduct repetitive drop tests under controlled parameters to assess product design robustness and packaging effectiveness.

Equipped with an advanced HMI-based control system, the machine allows easy setting of variable test parameters and continuous monitoring of cycle count and drop data. All recorded data can be easily exported in Excel format for detailed analysis and reporting.

Technical Highlights: