Major Highlights of the SPM

Equipped with an intuitive and user-friendly touch screen that simplifies operation, parameter setting, and monitoring of the complete punching process.

Integrated safety systems prevent accidental operation in manual mode, ensuring maximum operator protection and compliance with safety standards.

Designed with a modular tooling setup that enables changeover in less than 5 minutes, minimizing downtime and improving production efficiency.

The machine achieves a punching cycle time of just 10 seconds, ensuring fast and consistent performance for high-volume production.

Capable of handling various door panel sizes and designs with programmable punching patterns for different configurations and variations.

Features two independent operating sides, allowing simultaneous punching of two different panels to maximize productivity and reduce cycle time.

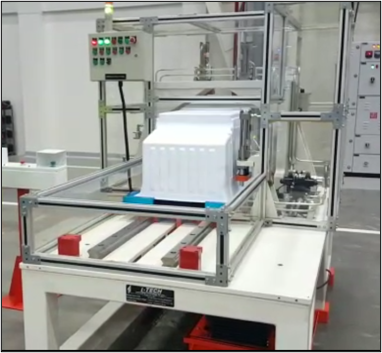

TM 265/350 Cabinet Liner Punching SPM

DC 220L Cabinet Liner Punching SPM

DC 195/205/225L Cabinet Liner Punching SPM

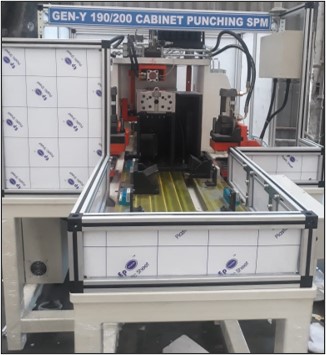

GEN-Y 190/200L Cabinet Liner Punching SPM

Major Highlights of the SPM

Equipped with an advanced, user-friendly touch-screen control (HMI) for seamless operation, real-time process monitoring, and parameter adjustments.

Multi-level safety interlocks and sensors ensure operator protection and prevent accidental operation during manual or maintenance modes.

Tooling and fixture design optimized for rapid changeover — less than 5 minutes — enabling high flexibility and reduced downtime between models.

Achieves a complete punching cycle in 20 seconds, ensuring enhanced productivity and consistent output.

Designed to accommodate multiple door liner sizes with customizable punching variations for each model.

Capable of producing DC, RC, FC, and FF models on a single platform, enhancing versatility and production efficiency.

Major Highlights of the SPM

Equipped with an intuitive and user-friendly touch screen that simplifies operation, parameter setting, and monitoring of the complete punching process.

Integrated safety systems prevent accidental operation in manual mode, ensuring maximum operator protection and compliance with safety standards.

Designed with a modular tooling setup that enables changeover in less than 5 minutes, minimizing downtime and improving production efficiency.

The machine achieves a punching cycle time of just 10 seconds, ensuring fast and consistent performance for high-volume production.

Capable of handling various door panel sizes and designs with programmable punching patterns for different configurations and variations.

Features two independent operating sides, allowing simultaneous punching of two different panels to maximize productivity and reduce cycle time.

Door Panel Notching Punching SPM

Major Highlights of the SPM

Equipped with a high-precision Nordson glue dispensing unit for accurate and consistent adhesive application on glass door panels.

Integrated 6-axis robot ensures uniform glue distribution with precise path control, reducing material wastage and improving bonding quality.

Machine features two independent pressing stations for simultaneous assembly operations, enhancing cycle efficiency and output.

User-friendly touch-screen control panel for easy operation, parameter setting, and real-time process monitoring.

Modular design enables rapid changeover between different door models, minimizing downtime and setup effort.

Controlled dispensing parameters and automated pressing sequence ensure consistent bond strength and repeatability across all assemblies.

Integrated safety interlocks and sensors ensure safe operation during manual intervention and maintenance.

System supports real-time process data logging and fault diagnostics for improved process traceability and maintenance planning

Glass on Door Pressing SPM

Major Highlights of the SPM

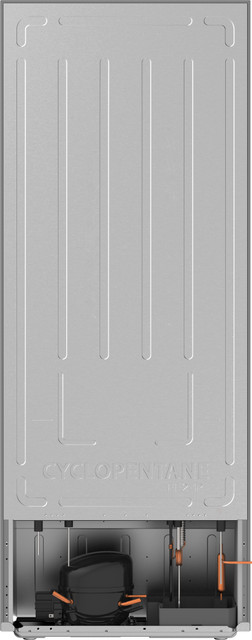

Designed to bend different types and sizes of refrigerator back panels with high accuracy and repeatability.

Equipped with a fully automated servo-driven changeover mechanism, enabling quick and precise adjustment between panel variants without manual intervention.

Servo-controlled motion ensures consistent bending angles and dimensions across all panel types, maintaining superior quality standards.

Intuitive touch-screen control panel for easy operation, recipe selection, and process monitoring.

Heavy-duty frame and precision components ensure long-term stability and vibration-free operation.

Integrated safety interlocks and sensors to ensure safe operation during manual and automatic modes.

Back Panel Bending SPM